Have Revit families improved in the last ten years?

This post kicks off our new REWORKED series of free content collections. Each collection in this series will take existing pieces of Revit content, highlight what’s wrong with them (and why it matters), and then showcase how we rebuild them to Kinship standards. We’ll wrap up by comparing the originals with our improved versions.

We’re not here to name and shame content creators. Instead, our goal is to highlight common mistakes, explain their impact, and demonstrate how they can be avoided.

Today’s focus is on isolating valves! We’re looking at the D171A ball valve from Crane, the 47XU-F gate valve from Crane and a butterfly valve from Brymec.

CraneFS_BallValve_D171A.rfa

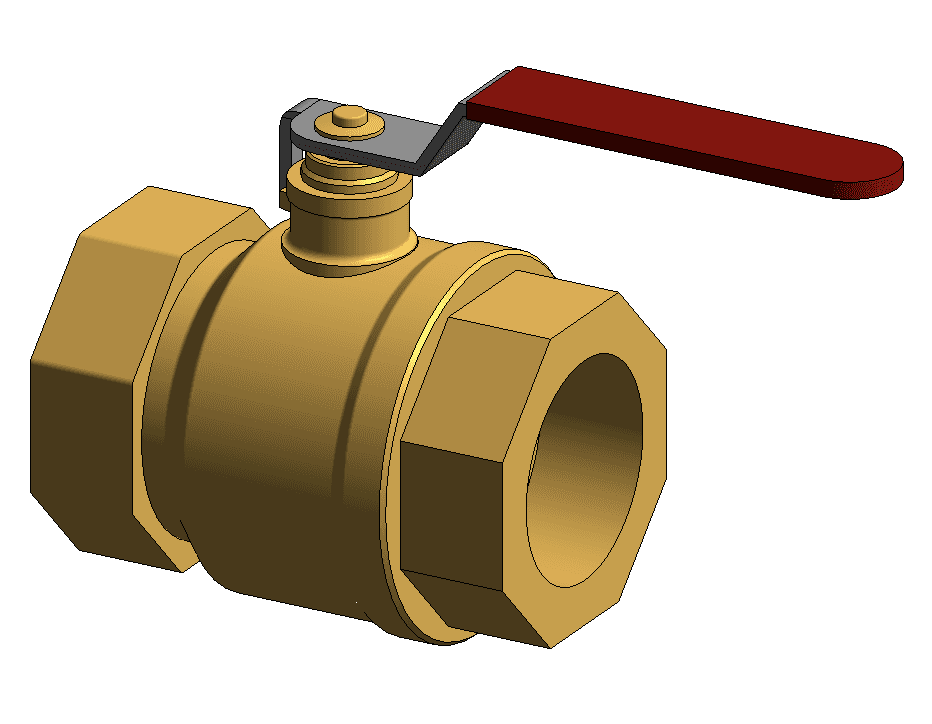

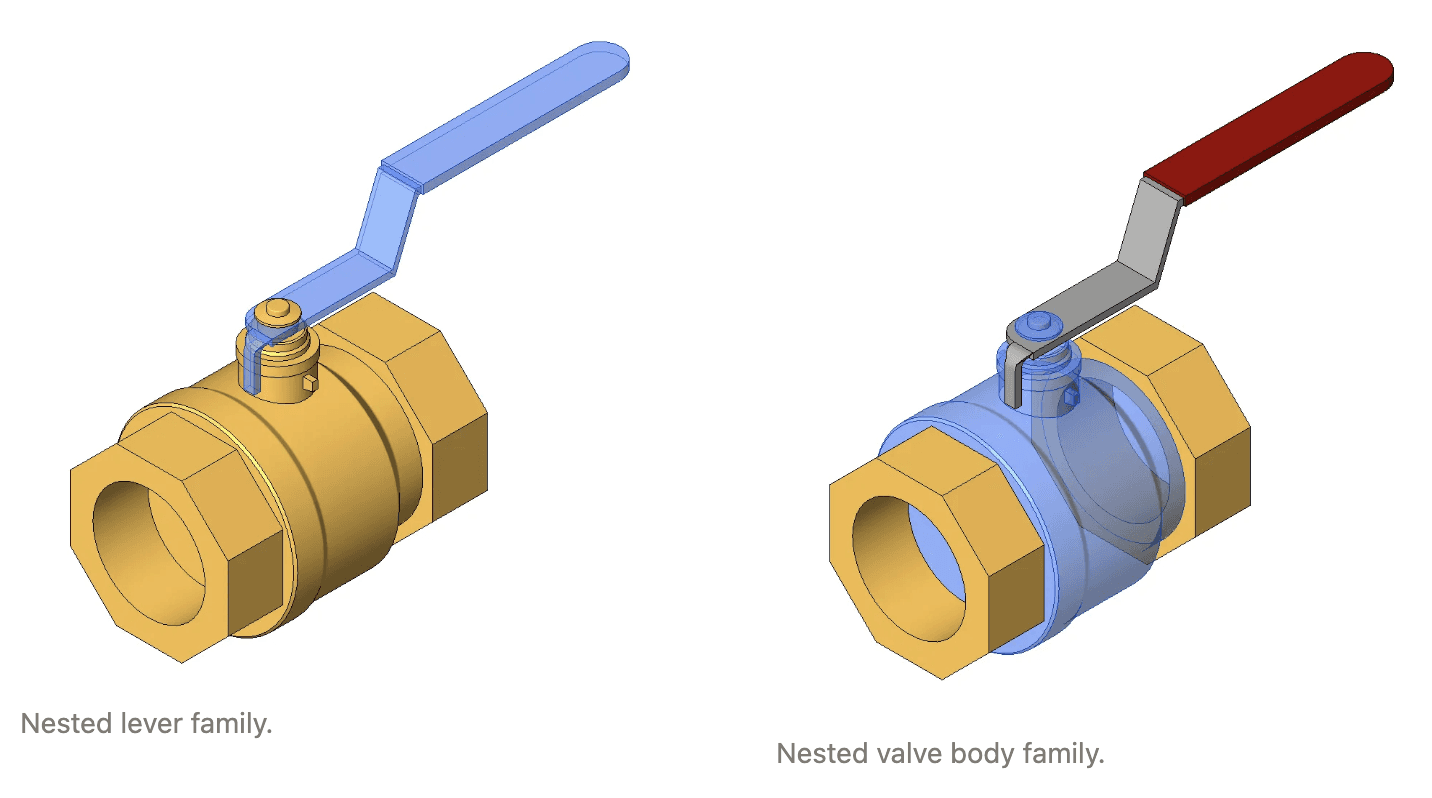

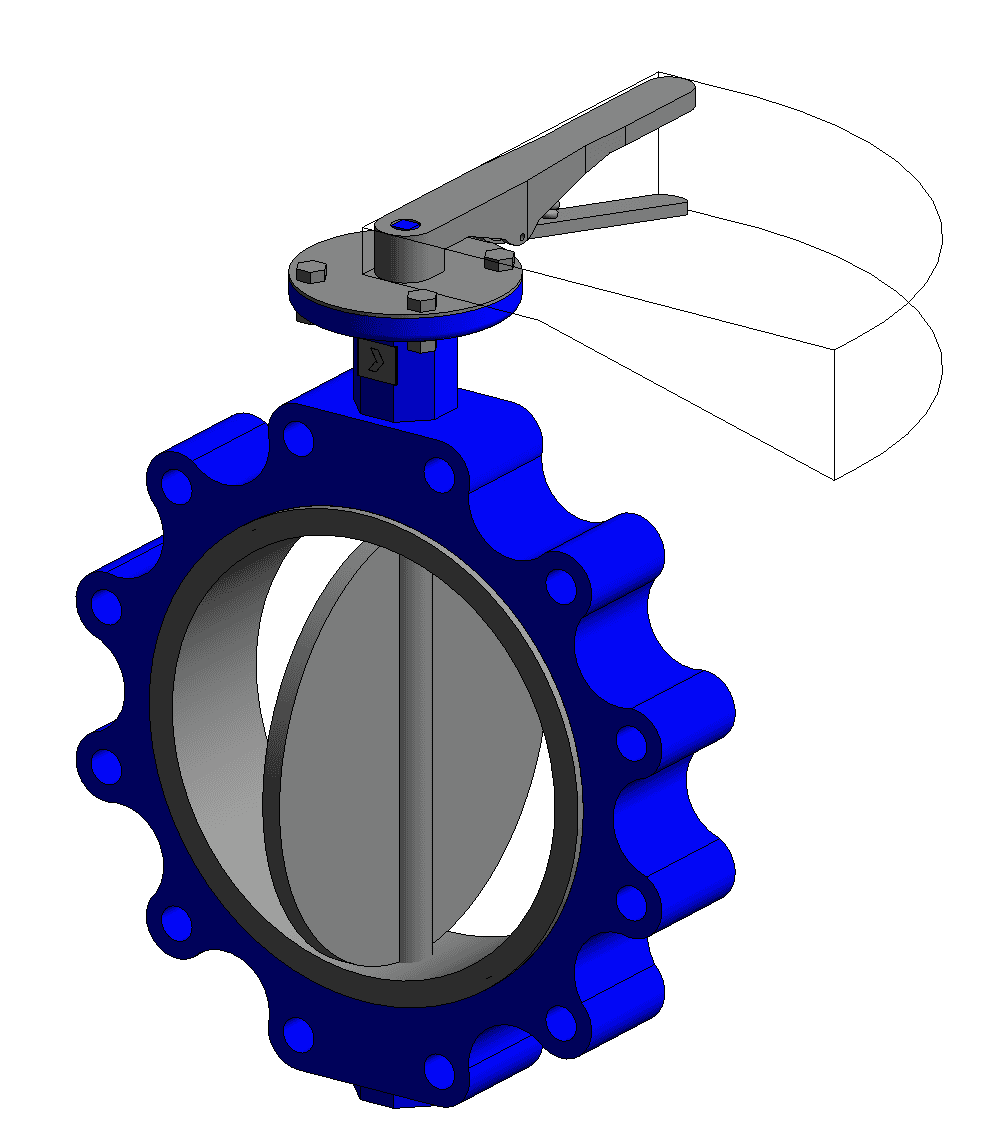

Let’s start with the D171A ball valve from Crane. Below is an image of the original family.

Original ball valve D171A family.

While the family certainly looks like the manufacturer’s product, there are numerous issues affecting its usability in a Revit project.

Poor Naming Convention

The standard set by Autodesk for naming valves is as follows:

The original family’s name has nothing for range or connection type. And using the “D171A” in the family name only helps if you already know the valve and Crane products, which most users will not.

In addition, the manufacturer should not be the first part of the name. Because Revit orders families alphabetically, this valve ends up grouped near Commissioning Sets and Check Valves, making it awkward and inefficient to switch between this and other ball valves within a project.

Large File Size

The size of the family file is 1.2 MB. That’s 40% larger than what’s acceptable. Valves should generally aim to be between 400-750KB. A threaded ball valve in this size range is one of the most frequently used in pipework systems, so it needs to be as efficient as possible. This oversized family will slow down your project workflow. The reasons behind the excessive file size are covered in more detail below.

Incorrect Connections

Be careful! This is a threaded connection ball valve, but the connections have been mistakenly set to copper ND sizes. So for example, instead of 50mm Nominal Diameter, the family uses 54mm ND. If you use this valve on a threaded pipe type, Revit will automatically add reducers at both ends. This creates fittings that don’t exist in real life, which is a very serious oversight by the content suppliers.

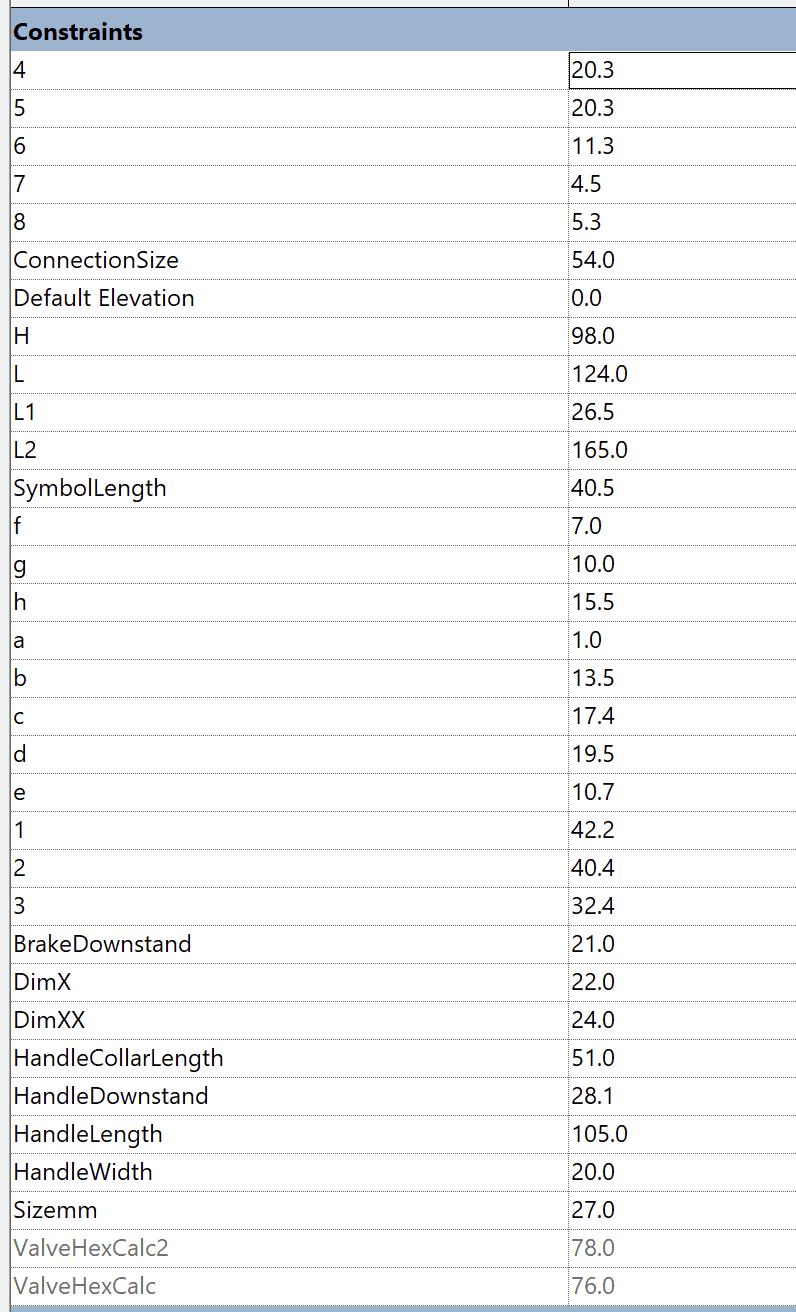

Overly Detailed Geometry

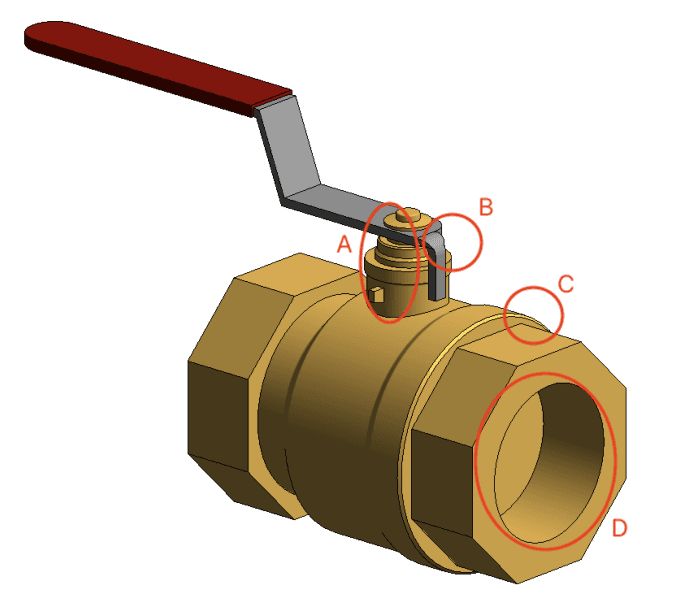

There are at least four areas where there is too much detail in the 3D geometry. Below is an image showing the different areas involved, followed by a description of each.

A) The stem has too many edges/faces in the revolve and even filleted edges. This means that the stem alone has more detailing than the valve body.

B) The lever has detailed geometry, which is unnecessary.

C) Chamfered edges are also not needed.

D) Socket threads are modeled internally, but connectors are on the socket face. This extra geometry is invisible when dropped into a pipe and inflates the file size.

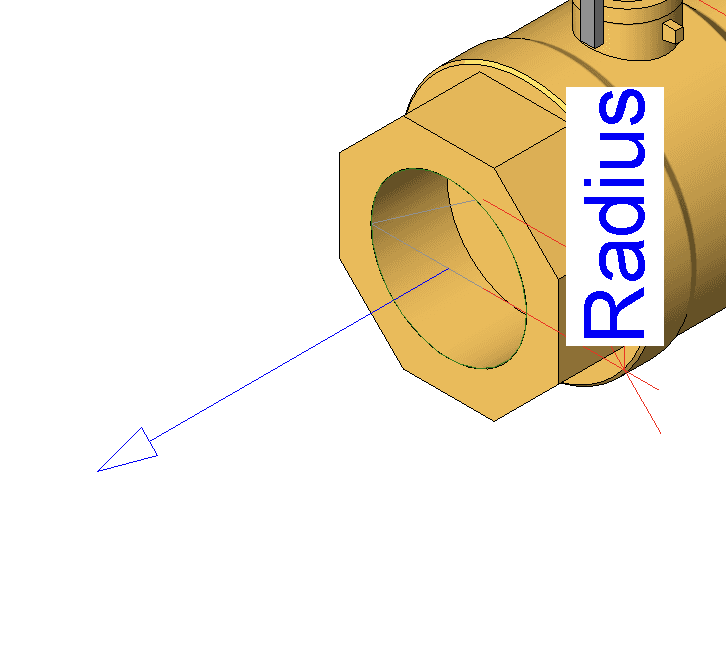

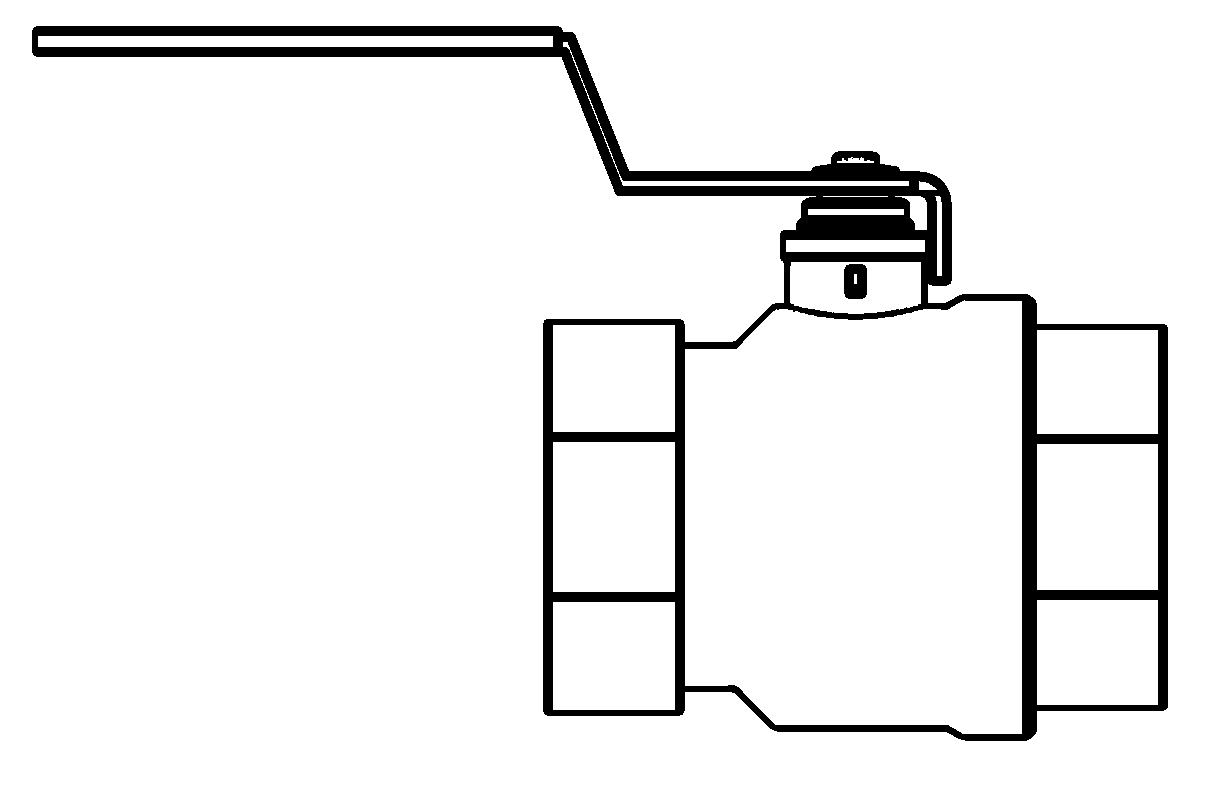

The excessive detail increases file size, but none of this helps MEP coordination or project deliverables. In fact, close proximity of faces and edges just creates obtuse linework in your deliverables.

Image showing thick line work representing the deliverable drawing.

Joined Geometry

The stem and body are joined, which yet again increases file size. It may creates a nice intersection edge at a close zoom. No one needs this in a real project.

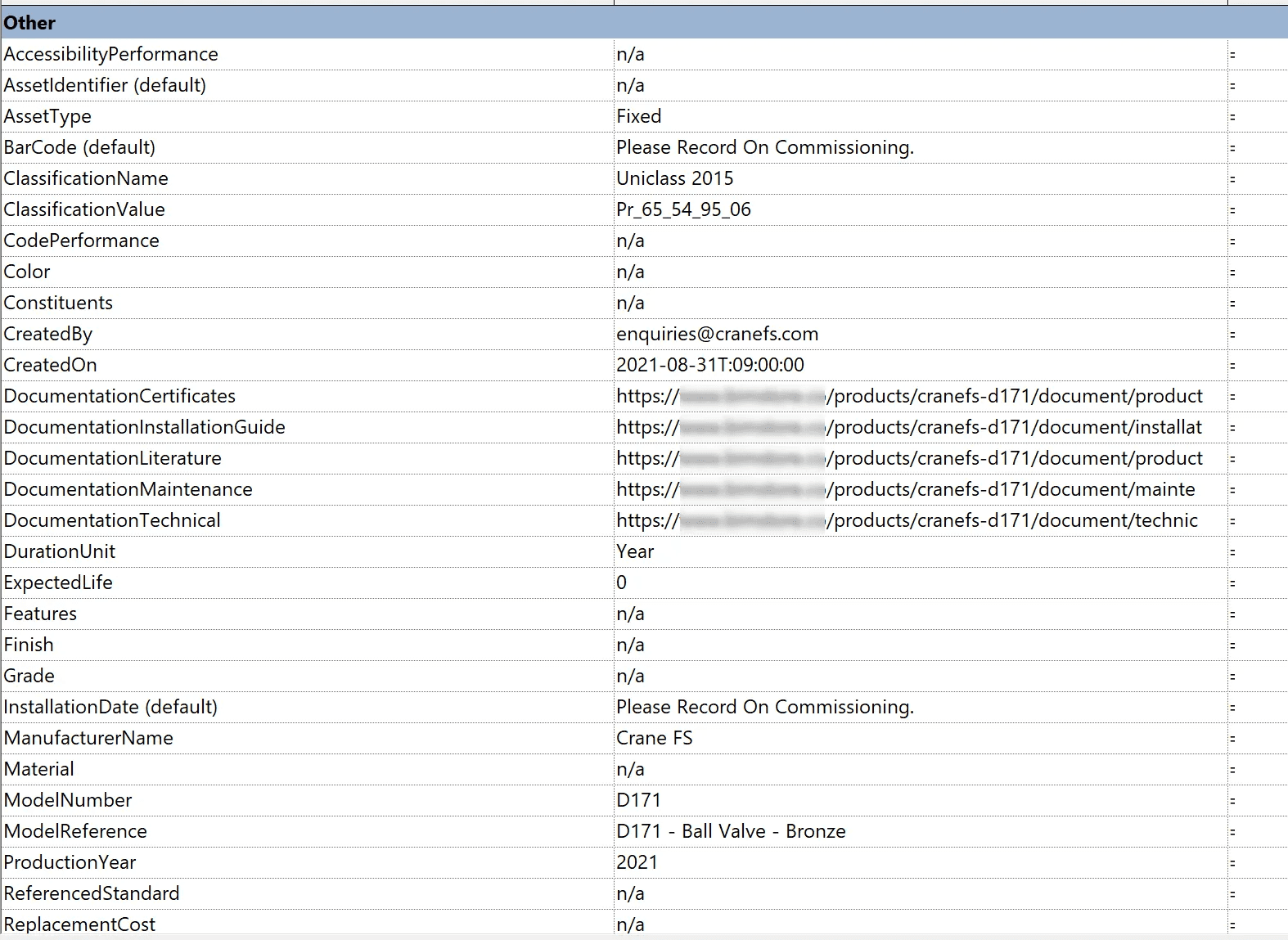

Unnecessary Nesting

The body and lever are both nested elements in the Revit family. Unnecessary nesting is a result of the content creator putting themselves first, before the end user. These elements could have been redrawn from scratch. Re-using nested elements saves the creator time, which means they make more profit, but at the expense of the the family itself and the end user. Simply put, they’ve sacrificed file size and user workflow for the sake of their own convenience.

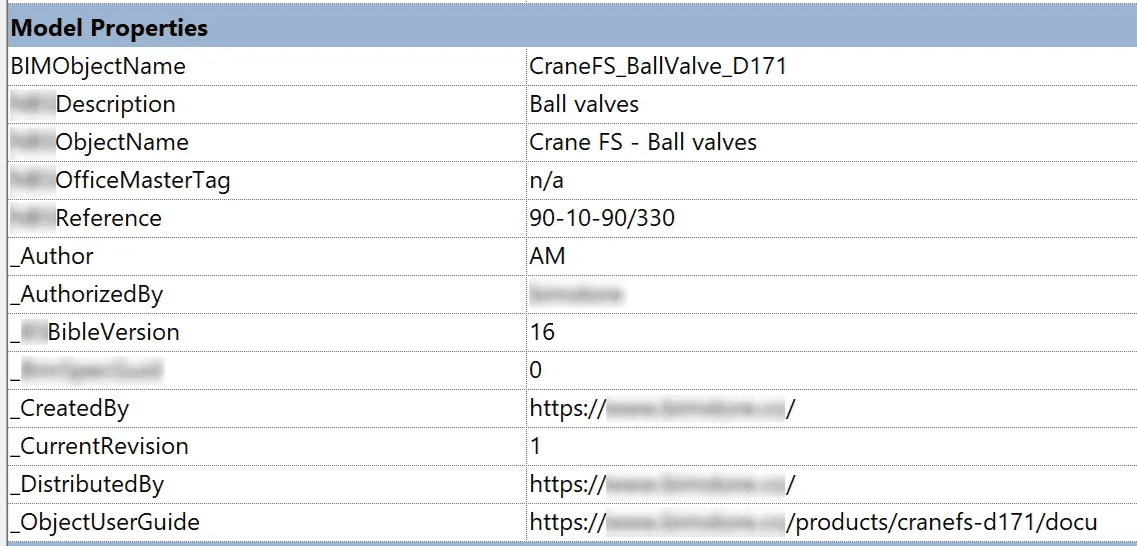

Useless Metadata

There are a bunch of parameters with “n/a” listed as the value, while others have duplicated values. Then, as you can see in the image below, four of them just show information about the content creator (including broken links). In the list of 29 parameters, it’s arguable that only five have any value.

In this image, there are 13 parameters that just give information about the content creator.

In the next image below, we see both poorly named parameters and convoluted structure.

No Type Catalog

This family does not use a type catalog. It is recommended best practice to use a type catalog if you have more than five types (as this family does). Using a type catalog helps reduce the number of unwanted types in a project, while also making it easier to maintain and update the family over time.

Too Many Controls

There are too many control buttons. It flips so many times it doesn’t work with the rotating buttons, so you end up not knowing how to control the valve!

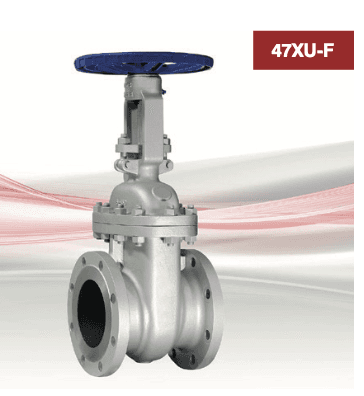

Pipe-Valve-Crane-47XU-F_Cast_Steel_Gate_Valve.rfa

Next let’s dive into this gate valve from Crane. Firstly, it’s important to note that this family is made by the same content creators and for the same manufacturer as the first family. So inconsistency is a big issue.

Broken Family

The valve is simply broken! Honestly we could stop the review at this point. The family won’t load correctly into Revit because of critical issues with the geometry.

Poor Naming Convention

This valve has the same issues as with the previous valve.

Missing Material

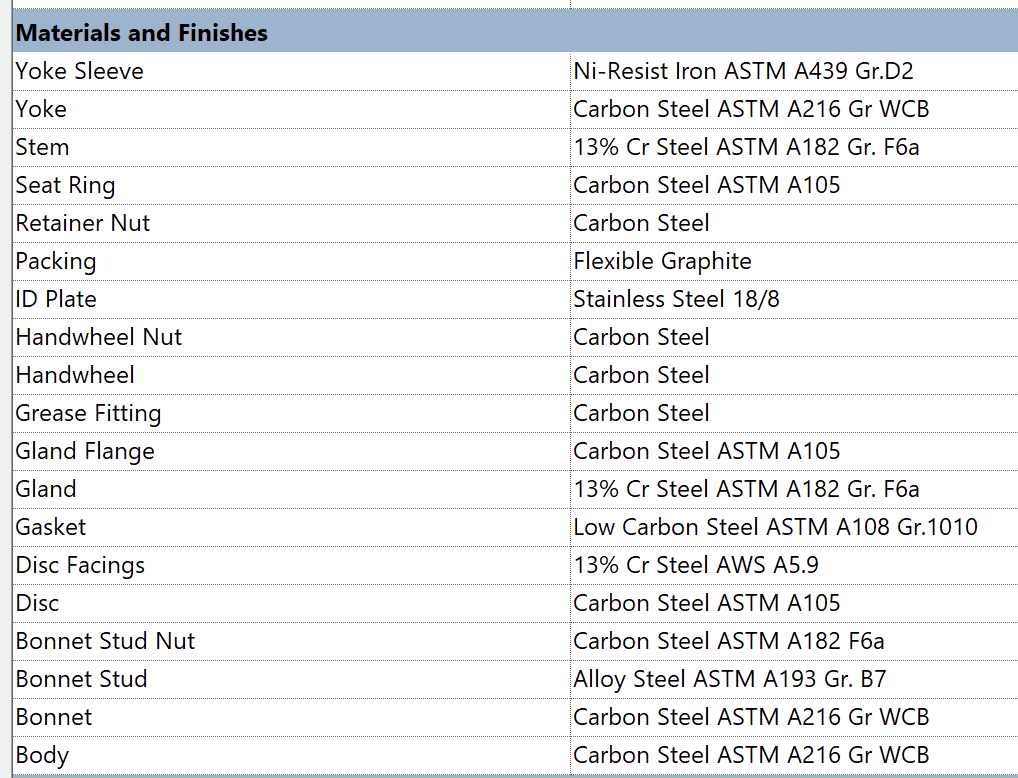

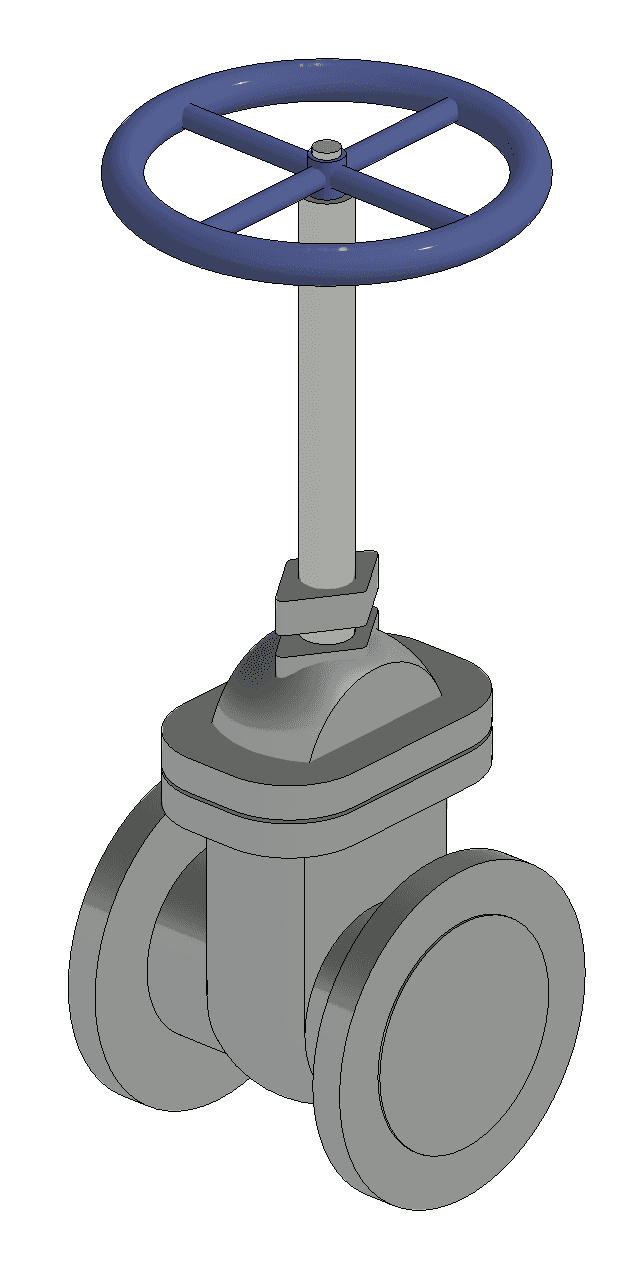

The family has only one material associated to all geometry. It should have a blue material for the handwheel as shown in the image below.

There are also 19 parameters dedicated to material metadata. That’s an enormous amount of overhead for something that still doesn’t produce correct results.

Large File Size

This family is even worse than the previous one in this regard. The size of RFA file is 3.2 MB. That’s 300% larger than acceptable!

Overly Detailed Geometry

Like with the previous family, this gate valve is riddled with over-detailing (it’s a disease!). And just like the previous family, this is the main culprit behind the bloated file size.

A, B & C) There’s simply no need for this amount of detail, especially for the bolts through the flange.

D) This is a flange. In practice, the pipe’s mating flange would connect directly against this flange’s raised face. The internal hole adds no functional value, as it’s completely hidden once the two flanges are joined. See the image further down in this section.

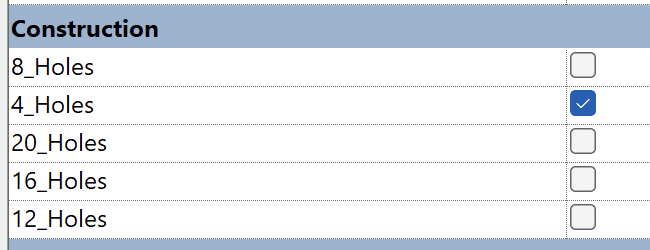

E) This is one of my pet peeves – bolt holes through a flange do not need to be modeled in Revit. They don’t match the pipe flange in Revit, and they’ll just be hidden anyway (see image below). What makes it worse is that the family actually has parameters to change the number of holes! Adding parameters to control the number of holes is a needless complication that benefits nobody.

To be honest, there are even more issues with this family. But in the interest of time and staying sane, let’s move onto the last valve.

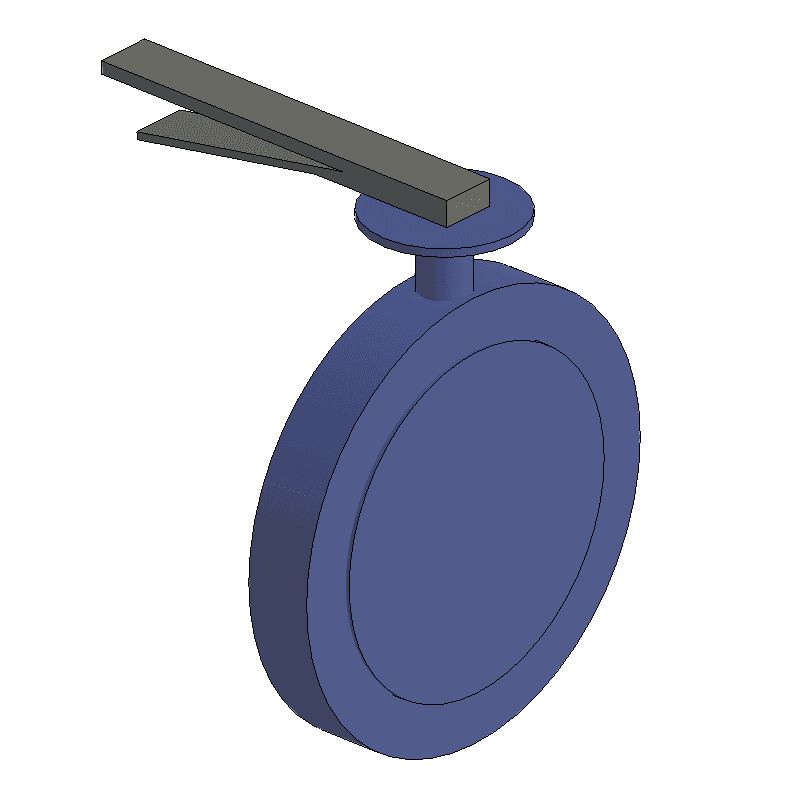

Plumbing_Valves_Brymec_38949_Fully_Lugged_Butterfly_Valve_Ductile_Iron_WRAS_PN16_10_Inch.rfa

We’ll run through this final valve quickly. By now, you will know why the highlighted points are problematic.

Broken Family

Revit throws a different warning than with the previous family, but a critical warning nonetheless. The family is simply unusable in Revit.

Poor Naming Convention

We only need to look again at the recommended naming from Autodesk (see first family) to identify multiple issues with the naming.

Large File Size

While this family is the best of the lot, it’s still too large at 1.1 MB.

Incorrect Usage of Lookup Table

For some reason, the family uses a lookup table rather than a type catalog. While lookup tables make sense for pipe fittings, they don’t make sense for valves (pipe accessories). It didn’t work in our test project.

Overly Detailed Geometry

There are so many elements here that don’t need to be modeled for Revit – fully lugged geometry, the internal disc, flange bolt holes, nuts, bolts and even the spring within the lever.

Our REWORKED Valves

We’ve reworked these valves to our standards for high-quality, high-performance Revit content. Where the valve has a lever, we have provided an instance option to have the valve open or closed. There is no nested geometry. No over-detailing. No messing around.

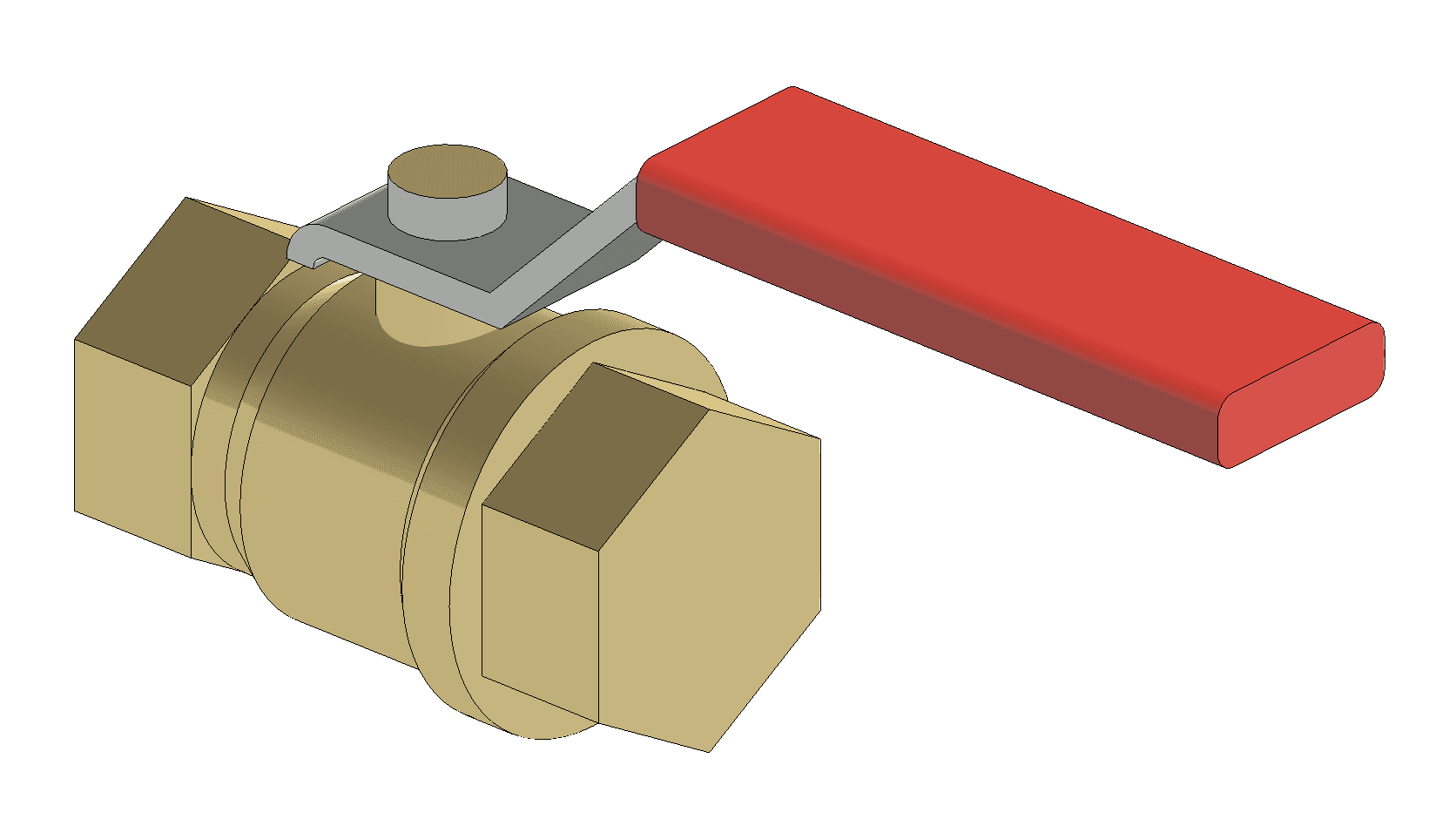

Ball Valve-Crane-15-50 mm-Threaded FxF-DZR-PN25.rfa

File size is 536 KB.

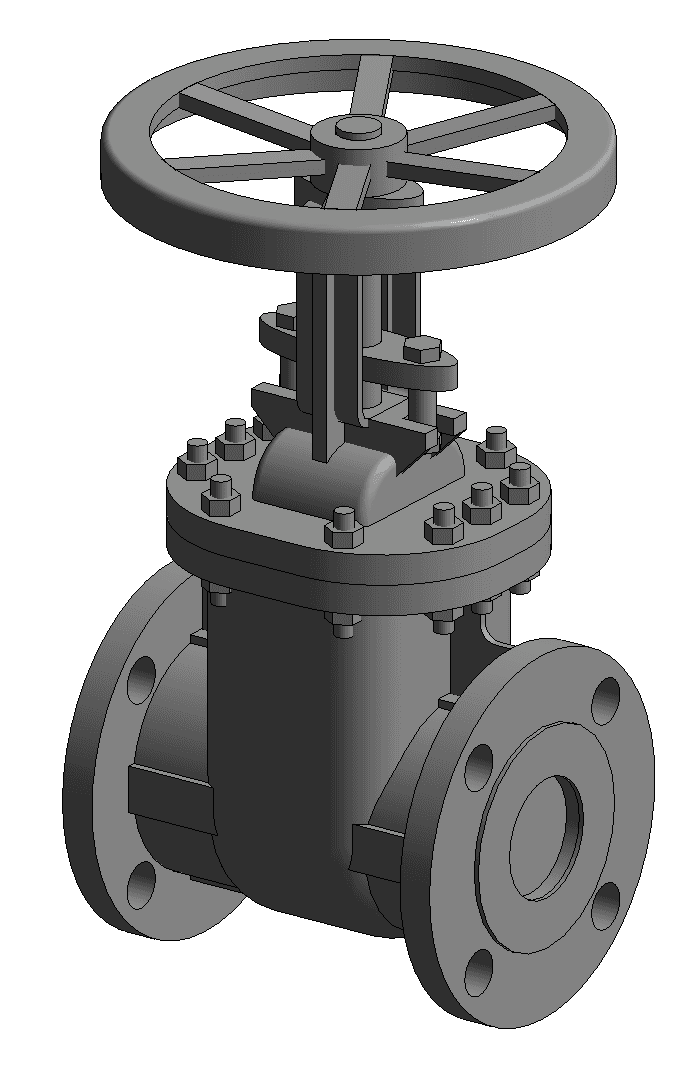

Gate Valve-Crane-2-24 inch-Flanged-CS-Class 150.rfa

File size is 688 KB.

Butterfly Valve-Lugged-Brymec-50-300 mm-Flanged-DI-PN16.rfa

File size is 556 KB.

Get the Collection

Click here to view and download the full collection.

Collection Content List

Threaded ball valve from manufacturer Crane.

Flanged gate valve from manufacturer Crane.

Flanged fully lugged butterfly valve from manufacturer Brymec.

Author

Chris Constantinou

Reading time

14 min

Share